Accreditation and certification

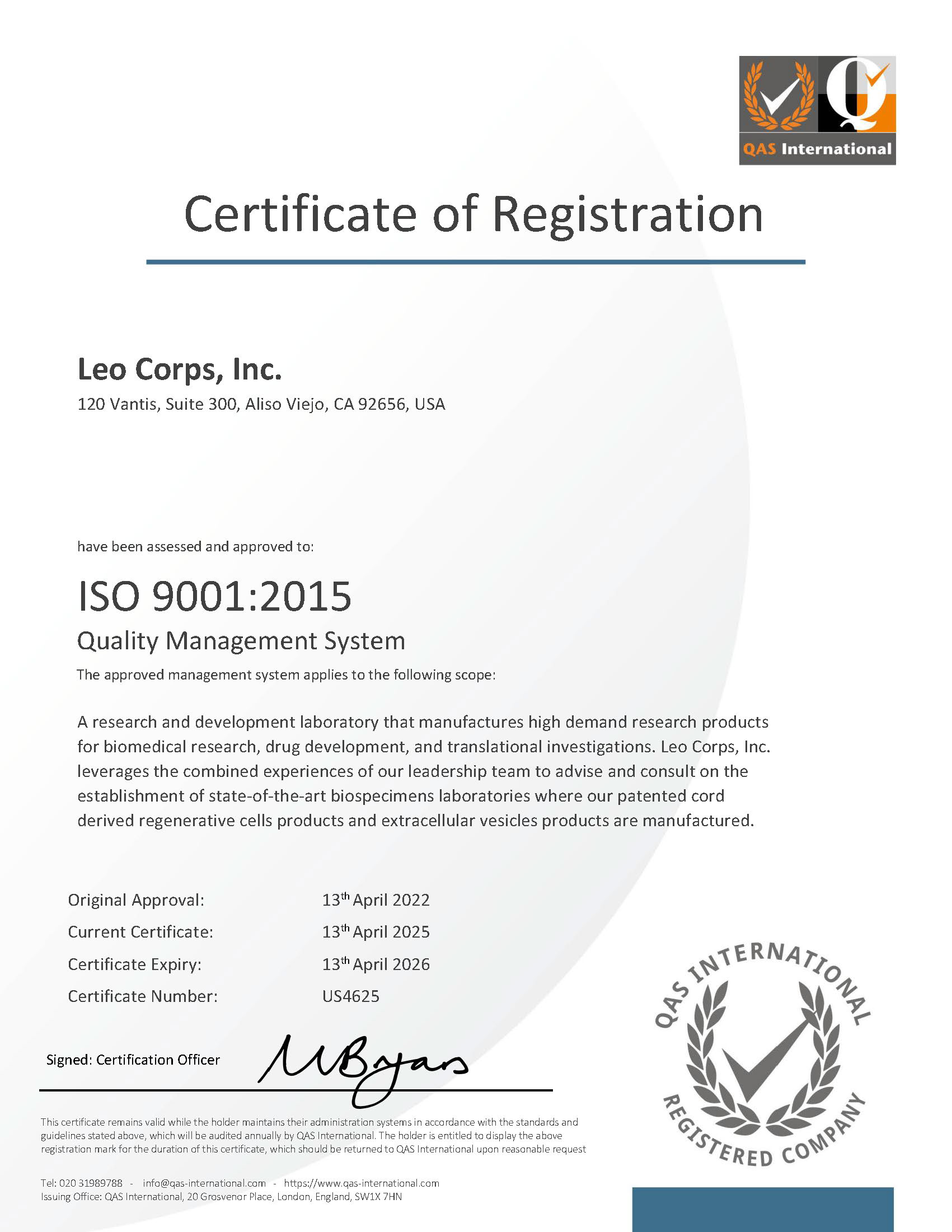

Establishing customer trust is essential for success in biotech and life sciences research, doubly so when operating in international markets. In many ways, this is easier said than done. Companies must carefully navigate the requirements of regulatory bodies while adapting their messaging to different cultural standards and market pressures.

Fortunately, demonstrating a dedication to thorough quality management practices is much more straightforward. Companies can do so by getting ISO 9001:2015 certified.

Headquartered out of Switzerland, the International Organization for Standardization (ISO) is an independent organization dedicated to standards development. ISO 9000:2015 certification is not performed by ISO, however. Instead, audits are conducted by outside agencies who are themselves carefully vetted.

To be ISO 9001:2015 certified, auditors must review the organizational structure, assess employees, and inspect processes[1]. Organizational efficiency, safety, and QMS processes are assessed at every level of a company. Classically, these inspections were performed in person, but the COVID-19 pandemic has required the adoption of virtual auditing for specific processes and situations.

A key benefit of being ISO 9001:2015 certified is that implementation of the required QMS procedures improves the quality of products, services delivered, and the customer experience. ISO 9001:2015 certification requires producing and maintaining records of product specifications and test results, ensuring accountability that drives better performance. Moreover, certification entails establishing a transparent line of communication with clients about expectations regarding service. By improving and ensuring the highest degree of quality standards, companies can engender client trust and may help justify the price of expensive services.

Safety is both a moral and financial imperative. A poor safety culture puts both clientele and employees at risk. The human cost of some errors can range from minor injuries to the loss of life in worst-case scenarios. In addition, such incidents can result in costly legal fees and fines from regulatory agencies. The process of ISO 9005:2015 certification requires that companies identify and address potential hazards that could put all parties in harm’s way.

ISO 9005:2015 certification can substantially reduce costs for companies by streamlining processes up and down an entire organization[2]. For example, identifying and improving weak points in the production line can help avoid wasted components and work hours lost by remaking out-of-spec products. Likewise, a standardized QMS can ensure that products are not returned to the company, avoiding associated costs and the loss of customers. The certification process also helps identify organizational redundancies and highlights opportunities for process refinement and cost reduction.

However, there are costs associated with the certification process. For example, companies must pay for the total time an auditor is on-site, as well as their travel expenses if performed in person. The total cost of an inspection, therefore, depends heavily on the number of employees, risks associated with the site and products, and pre-existing ISO certifications. Regardless, the benefits of certification greatly outweigh the associated costs.

All of the above benefits of ISO 9005:2015 certification help companies by improving their public image and customer impressions. Many potential customers see a lack of certification as a red flag that gives them some pause. This is doubly so for companies that are headed to or have production facilities in countries and regions that are unfairly stigmatized in other parts of the world. ISO 9005 certification, therefore, backs a company’s reputation less subjectively than word of mouth.

At Leo Corps, Inc., we understand that the quality of our products impacts project development and, more importantly, the projects of scientists and clinicians who depend on our products or the discoveries made from them. As a result, we are proudly ISO 9001:2015 certified. Our dedication to quality is core to our mission and implemented in all of our processes. To learn more about our QMS processes, contact us today!

References:

1. Standardization, I.O.f., ISO 9001:2015 Quality management systems — Requirements, in 03.100.70 – Management systems – 03.120.10 – Quality management and quality assurance. 2015, International Organization for Standardization: ISO. p. 29.

2. IRCA, C. ISO 9001:2015 and calculating the cost of quality. [cited 2022 April 24th]; Available from: https://www.quality.org/knowledge/iso-90012015-and-calculating-cost-quality.

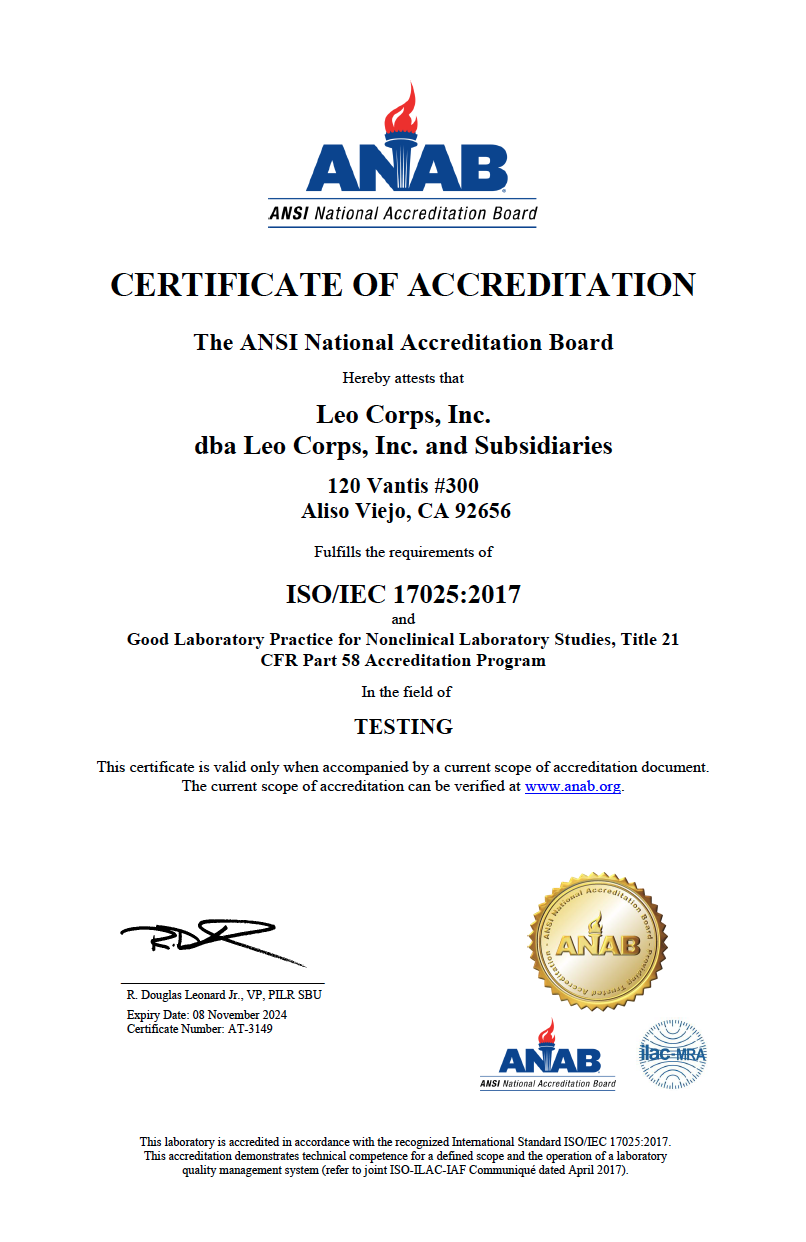

ISO/IEC 17025:2017 (Importance of Biological Testing ISO/IEC 17025 accreditation)

Performing laboratory biological testing entails a dedication to accuracy and attention to details. Doing so requires thorough quality management processes and procedures to avoid internal errors that could turn into external ones if missed. Given the opportunity, most companies will assure potential clients that they only provide the best and most reliable results. Assurances only go so far; laboratory testing and calibration service providers need to prove their ability and track record to clients. One way to do so is through ISO/IEC 17025 accreditation.

What is ISO/IEC 17025 Accreditation?

ISO/IEC 17025 is an internationally recognized standard for lab testing quality management systems (QMS), devised in tandem with the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC)1. ISO/IEC 17025 accreditation ensures that companies that perform laboratory testing have QMS processes in place to ensure accuracy and reliability of results they provide.Likewise, the standard ensures that the equipment and clean rooms companies use during testing are up to date with their calibrations and validation. It is similar to ISO 9000 certification, except that it applies specifically to companies performing testing and calibrations.

How does a company get ISO/IEC 17025 Accredited?

The first step to getting ISO/IEC 17025 is gap analysis2. This entails a thorough review of QMS processes to identify any weak points at the general, structural, and management levels. Once any gaps are identified, the information gleaned should be used to help plan improvement strategies moving forward. These plans should be made with input from all teams involved. Broad cooperation between departments with fruitful lines of communication helps speed implementation and avoid any missed points of improvement along the process. This includes training all employees in the new processes. In addition, it is essential to maintain detailed documentation about process changes to ensure transparency, accountability, and clarity. The next step is to internally approve and implement the new QMS processes.

Once the new QMS has been implemented, it is imperative to check it internally before moving on to an outside auditor. It is recommended to operate under the newly initiated QMS processes for three or more months to collect necessary records and find points of improvement. After this testing period, organizations should perform internal audits based on the standards of accreditation bodies. If these standards are met, an approved accreditation body should be contacted to perform a thorough external audit. Upon successful completion of the audit, the body awards ISO/IEC 17025 accreditation. Otherwise, it’s back to the drawing board to address concerns raised during the inspection.

What Does 17025 Accreditation Mean for You?

If you are searching for laboratory testing services or looking for reliable testing results to validate or use products for decision-making purposes, ISO/IEC 17025 accreditation tells you that a company can ensure reliable results you can count on for your research or medical testing needs. Moreover, this accreditation applies internationally, meaning that the results you receive in one country are still up to standards in another, simplifying multinational operations. Finally, ISO/IEC 17025 accreditation demonstrates a dedication to quality results and, therefore, quality services.

Operating in research or clinical spaces requires accurate and reliable laboratory results especially when performing hematology and cytometry analysis. At Leo Corps, Inc., our hematology and cytometry analysis services are backed by ISO/IEC 17025 accreditation, exemplifying our drive to offer our clients quality services and testing results they can count on for research and clinical purposes. Likewise, we perform batch product viability and purity testing for a wide range of clients, generating accurate, reliable, and unbiased product data analyses and reports. Our state-of-the-art facility uses cutting-edge equipment that is constantly calibrated and maintained to meet or exceed ISO/IEC 17025 standards. If you are searching for hematology testing and cytometry services for biological products or drug development consulting, contact us today to see how we can help.

1. ISO/IEC 17025 – testing and Calibration Laboratories. ISO. https://www.iso.org/ISO-IEC-17025-testing-and-calibration-laboratories.html. Published March 11, 2020. Accessed November 16, 2022.

2. Patrick B. Steps to ISO 17025 accreditation. ISO 17025 Store. https://17025store.com/step-by-step/. Published April 20, 2020. Accessed November 16, 2022.

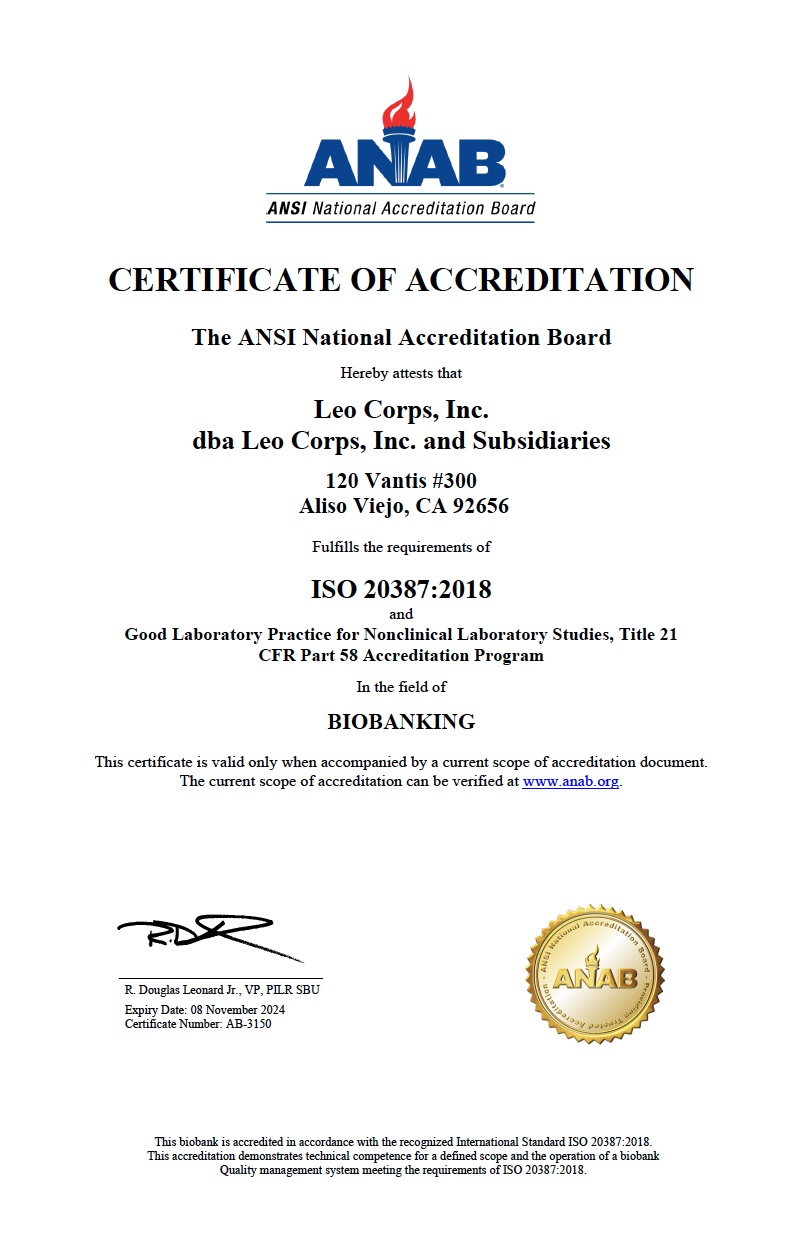

ISO 20387:2018 (Importance of Biobanking and Bioprocessing ISO 20387 accreditation)

Working with biological samples requires special consideration. Samples can be difficult to extract and prepare and often are in limited quantities. Moreover, obtaining new, equivalent samples can be downright impossible, especially when handling, processing, and storing biomaterials from human subjects. As a result, companies working with biological samples cannot afford to choose biobanking services carelessly. They need to be assured that a biobanking service provider can properly handle, store, and process biological materials and related data as needed. The best way biobanking providers can demonstrate competence is through ISO 20387:2018 accreditation.

What is ISO 20387:2018 Accreditation?

ISO 20387:2018 is an internationally recognized standard for biobanking and bioprocessing providers designed by the International Organization for Standardization (ISO)1. This standard provides requirements and guidance to ensure effective processes and thorough quality management systems (QMS) for companies and organizations that offer biobanking and bioprocessing services and/or products. In doing so, ISO 20387:2018 accreditation processes help ensure the safety, purity, and efficacy of biological samples during short- and long-term storage.

What are the Requirements for ISO 20387:2018 Accreditation?

The requirements for ISO 20387:2018 accreditation generally fall into four categories: structural requirements, general resource requirements, personnel requirements, and infrastructure & environment requirements2. To meet structural requirements, a biobank must demonstrate that it is a legal entity and provide in-depth information regarding the organization’s internal structure and interdepartmental relationships. In addition, key personnel must be able and approved to perform adequate monitoring services. To meet general resource requirements, an organization must have the physical resources to maintain and protect samples, especially in the event of emergencies. This entails having backup generators and freezers and always keeping employees on call. Meeting personnel requirements means ensuring employees and staff have the training, education, and skills necessary to perform their duties to the highest standard. Finally, infrastructure & environmental requirements are set in place to make sure a company has the infrastructure needed to perform necessary operations with samples and maintain properly secured data systems.

How Does a Company Attain ISO 20387:2018 Accreditation?

Obtaining ISO 20387:2018 accreditation requires going through an intense multi-level quality check process when it comes to biobanking and bioprocesses. The first step to getting ISO 20387:2018 accreditation is to identify any weak points in biobanking procedures and QMS. Once any weak points are identified, this information can be used to plan improvement strategies. Cooperation across the organization is key, so all parties need to be involved in the planning and implementation processes. In addition, documentation about process changes is pivotal to ensure transparency, accountability, and clarity going forward. The next step involves approving and implementing the new processes for a given time before an internal audit is performed. If the results of the internal audit are positive, the company can schedule external auditing from an approved accreditation organization.

What Does ISO 20387:2018 Accreditation Mean for You?

Selecting a biobank is pivotal if your operations depend on the safe short- or long-term storage of biological materials. ISO 20387:2018 accreditation shows that a biobank has gone through all the proper processes to ensure its operations are up to standard. As a result, accreditation is an easily identifiable symbol of competence and quality. Moreover, this process is not bound to a single nation, meaning you can trust operations no matter the locale. Finally, getting ISO 20387:2018 accreditation shows that a biobanking organization is willing to put its processes to the test, demonstrating transparency. As an ISO 20387:2018 accredited company, Leo Corps, Inc. is dedicated to processing and storing biological materials entrusted to us. If you want to learn more about our services, products, and QMS processes, please contact us today.

1.ISO 20387:2018. ISO. https://www.iso.org/standard/67888.html. Published August 3, 2018. Accessed November 16, 2022.

2. ISO. https://dgn.isolutions.iso.org/obp/ui#!iso:std:iso:20387:ed-1:v1:en. Accessed November 16, 2022.

Registered: CAP# 936439701

ISBER ( International Society for Biological and Environmental Repositories) Endorsed

IBBL ( Luxembourg Institute of Health | Integrated Biobank of Luxemburg ) Registered